ultrasonic testing 6db drop method|6db drop defect length : sourcing In manual ultrasonic inspection, the most commonly understood practice for length sizing discontinuities larger than the beam width is the 6 dB drop method. However, peaking the signal then. Resultado da The most intimate act of any animals (including humans) is often present in Comic Books. According to Freud, along with aggression, sex is what drives every action. Humanity, like every other .

{plog:ftitle_list}

Minecraft Classic is a free online multiplayer game where yo.

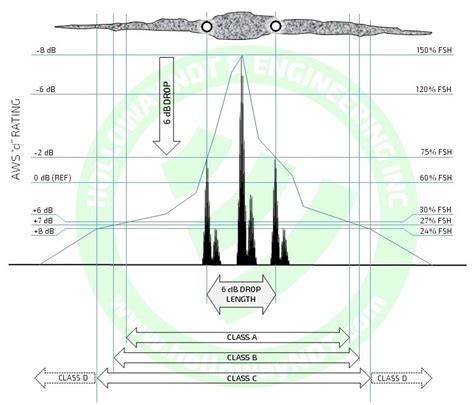

In manual ultrasonic inspection, the most commonly understood practice for length sizing discontinuities larger than the beam width is the 6 dB drop method. However, peaking the signal then moving laterally to 50% signal height can often under size the length.

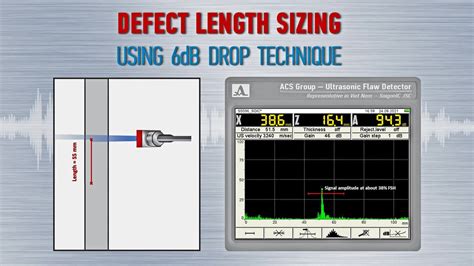

In manual ultrasonic inspection, the most commonly understood practice for length sizing discontinuities larger than the beam width is the 6 dB drop method. However, peaking the signal then. This video demonstrates measuring the length of a defect using ultrasonic angle beam 6dB drop method. Equipment: Olympus EPOCH1000i UT tester, 70 degree, 4Mhz, .A common procedure is the “6 dB drop technique”, demonstrated in the graphic below, in which the probe is moved from left to right while noting the two points where the maximum reflection . EWI will use the 6 dB technique when it is required by customers, but in other instances, our preferred method of flaw measurement is a high amplitude time based .

dB Drop. This is a common method used in ultrasonic testing. In this method, the UT probe is moved across the flaw and the 6 dB drop points measured. This measurement is related to the . The purpose of this paper is to review techniques that utilise ultrasonic bulk waves to size flaws. Flaws that are embedded within a component (i.e. remote from any surface) as .

For indications larger than the beam spread, echo dynamic sizing (sizing by probe travel, e.g. -6 dB drop method) is used and for indications smaller than the beam spread area amplitude .The 6dB drop method is commonly used for sizing of flaws. This technique is based on determining the end points where the ultrasonic signal amplitude from the flaw drops to half of .

The article discusses the three principal conventional manual ultrasonic sizing techniques: 6 dB drop technique, maximum-amplitude technique, and 20 dB drop technique. It provides .

Introduction. The propagation of low amplitude ultrasound. Ultrasonic characterization. Ultrasonic transducers. The principles of ultrasonic testing. Ultrasonic testing equipment. Ultrasonic flaw detection. Flaw sizing in metals. The testing of metals. The examination of non-metals and adhesive bonds. Training, certification and standards. Further reading. Appendices.Ultrasonic Methods of Non-Destructive Testing covers the basic principles and practices of ultrasonic testing, starting with the basic theory of vibration and propagation, design and properties and probes, and then proceeding to the principles and practice of the various ultrasonic techniques for different types of components and structures, both metallic and non .The Practical Guide to Ultrasonic Testing In the Real World ©2008 Andrew Cunningham ©2008 Andrew Cunningham Quick Calculations of the Wavelength (λλλλ) The wavelength is determined by the velocity of sound in the material, divided by the frequency

Such calibration blocks can be produced to validate the ultrasonic test method but are expensive and tend to be used only in applications such as nuclear vessel manufacture and critical offshore/process plant fabrication. . The size of a reflector is generally determined by the ‘6db drop method’, as illustrated in Fig. 3. . Using the #ACS_Group_Ultrasonic_Flaw_Detector in the #6dB_Drop or #20dB_Drop_Techniques:1. After the defect length is sized, the next step is depth sizing by.these amplitude-drop methods, the beam is scanned over the defect, which is then sized by measuring the relative decrease in signal magnitude compared to a reference value. . The limiting accuracy seems to be data analysis by the ultrasonic testing operator, since ultrasonic pulses feature a wide beam with a spectrum of frequ encies. A quick .We would like to show you a description here but the site won’t allow us.

The measured displacement using the 3dB difference from the midpoint gives this a 3.8mm 6dB spot size. For comparison of techniques the unfocused probe was evaluated using a steel rod 1.8mm diameter. Using the 6dB drop at the same waterpath, a 6dB beam width of .sizing (sizing by probe travel, e.g. -6 dB drop method) is used and for indications smaller than the beam spread area amplitude based sizing methods are used (like DAC . With the enhancements in ultrasonic testing (9) and metallurgy the sizing of small defects becomes increasingly important. Therefore, the questions arise: . In the September issue of Materials Evaluation, the American Society of Nondestructive Testing’s (ASNT) monthly journal, an article was published which highlights the shortcomings of the most widely used ultrasonic testing (UT) measurement technique.In the article “Improving on the 6 dB Drop Technique for Determination of Flaw Length,” the author . #ultrasonic testing 6db vs 20 db drop technique

Ultrasonic Methods of Non-Destructive Testing covers the basic principles and practices of ultrasonic testing, starting with the basic theory of vibration and propagation, design and properties and probes, and then proceeding to the principles and practice of the various ultrasonic techniques for different types of components and structures, both metallic and non . Ultrasonic Testing (UT) method is frequently used for non-destructive testing of aerospace composite structures. Defect-Sizing in these structures using simple -6 dB amplitude drop technique is difficult to achieve. . The above result shows defect oversizing when we select the maximum amplitude to apply the 6dB drop sizing. The defect size .

The above introduction provides a simplified introduction to the NDT method of ultrasonic testing. However, to effectively perform an inspection using ultrasonics, much more about the method needs to be known. The following pages present information on the science involved in ultrasonic inspection, the equipment that is commonly used, some of .In Phased Array Ultrasonic Testing (PAUT), images are typically formed through constructive and destructive superpositions of signals backscattered from flaws or geometric features. . Drawing a box using the -6dB drop method around the FBH always led to an IoU under 15%. On average, the lateral extent of the FBH using the -6dB method was . The 6dB drop method is best suited for ideal reflectors like side drilled holes in reference blocks and tends to fall apart when applied to real, irregularly shaped discontinuities (e.g. lack of penetration, casting voids, etc). . Rosenxt designs modular inspection systems for automated ultrasonic testing of heavy plates and . In a typical ultrasonic testing scenario, backwall reflections carry defect information that is not included in the direct ray path. . Amplitude-based sizing techniques such as the 6 dB drop method and its variants [9, 11] are normally dependent on the measurement of the specular reflection from a crack-like defect and are not suitable for .

Most important acronym in Ultrasonic Testing (3:02) FPADS Knuckle Video (2:55) Audio Review of Modules 1 to 3 Read Chapter 3 . Defect sizing technique-6dB Drop Lesson content locked

6db drop size

This video demonstrates how to measure the through wall dimension of a center line crack in a weld using an ultrasonic tester. This technique uses the 6dB d. The intuitive imaging of the plate damage was obtained using the ultrasonic inspection data. The damage can be identified and located utilizing the ultrasonic data, and it can be quantified by the 6dB-drop method. Impact damages size and impact energy is connected to establish a prediction model for impact damage size.

6 dB drop technique UT ll Ultrasonic testing sizing of indications ll NDT Level 2Join this channel to get access to perks:https://www.youtube.com/channel/UCP. Ultrasonic waves can propagate through thick, solid parts so ultrasonic testing is suitable for flaws far beneath the inspection surface, unlike methods which can only detect flaws on, or very close to, the inspection surface e.g. Eddy current testing (p.111f in [6]) and potential-drop techniques (p.113f in [6]); or methods which can only detect flaws on the inspection . Download figure: Standard image High-resolution image The N ultrasonic phased arrays shown in figure 1 are transmitted by one of the array elements and received by N arrays to form N × N full matrix signal data. The full matrix signal data collected on the reference sample are recorded as S b (ij), and the full matrix signal data collected on the sample to be tested are .

Sujatha Kumaran , Sheela Rani.B #2 # Sathyabama University, Jeppiaar Nagar, Rajiv Gandhi Road, Chennai 600 119, India 1 [email protected] 2 [email protected] Abstract—This paper deals with the estimation of width of top of sub assembly ring using Pulse Echo Ultrasonic Technique. Due to the effect of beam spread, the ring appears to be .

6 dB drop technique Note : In ultrasound, the -6 dB drop is widely used to measure the length or width of an indication. A -6 dB drop correspond to half the . Re: Weld Flaw Sizing Methods: With regard to weld testing and sizing flaws.: I am aware of the following ultrasonic sizing methods eg.: * 6db Drop: * 20db Drop: * Maximum Amplitude Method: * Tip Diffraction Method: Would it be possible to get a general comment from the UT experts that covers the following points:5- Basic Ultrasonic Test Methods - Through Transmission - Pulse Echo 6- Test Equipments Ultrasonic Probe Classification . - 6dB Drop Method - 20dB Drop Method - DGS Method . NDT Course Syllabus 14- Welds Type and Testing Procedure - Standard and Acceptance - .

core hardness tester price

web👆👆👆👆👆👆👆👆👆👆if you register using the link above, then I will add my naked photos ️ ️ ️ ️

ultrasonic testing 6db drop method|6db drop defect length